Products

News

- RH Water Filter: the perfect fusion of structural design and material selection

RH Water Filter is highly regarded for its excellent structural design and material select

- Revealing the high-efficiency filter material of RH Water Filter: ensuring clean drinking water for families

In today's era of health and environmental protection, choosing an efficient water filter

Stainless Steel & Plastic Faucet Water Purifiers Suppliers

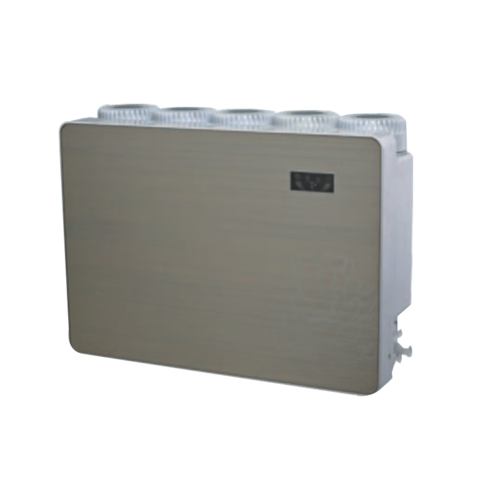

Stainless steel & plastic faucet water purifiers are filtration devices that attach to your faucet to improve the quality of tap water. These purifiers come in a combination of stainless steel and plastic components. The stainless steel parts provide durability, corrosion resistance, and an attractive appearance, adding a modern touch to your kitchen or bathroom. They contribute to the overall longevity of the purifier, ensuring it withstands regular use and maintains its functionality. Plastic components, on the other hand, are often used for filter housing and other non-structural parts. They are lightweight and cost-effective, making the purifier more affordable while still maintaining its effectiveness.

Food-grade transparent visual housing with the optional filter element. The faucet is easy to install, no electricity is used and no wastewater is generated

Food-grade transparent visual housing with the optional filter element. The faucet is easy to install, no electricity is used and no wastewater is generated

English

English 中文简体

中文简体